Center for Advanced Manufacturing and Materials Design Integration

An interdisciplinary research and development Center that consists of world-class expertise in materials, manufacturing, engineering design, business management, and logistics.

The Center for Advanced Manufacturing and Materials Design Integration is developing and transitioning new manufacturing technologies, providing workforce development, and improving the domestic manufacturing supply chain with a key role in strengthening advanced rural manufacturing in underdeveloped areas of Alabama.

Point-of-Need Manufacturing research and development at the University of Alabama is focusing on the production of items on demand at the location where the items are needed. This paradigm allows for radical transformation and simplification of traditional supply chains. This approach allows for the faster production of parts at a lower cost than can be achieved through traditional manufacturing methods. Research examples that our interdisciplinary team are advancing include:

Project Spotlight

Project Number: WP18-C4-1323

Project Title: Recycling and Reuse of Metal Alloys by a Single Solid-State Additive Manufacturing and Repair Process

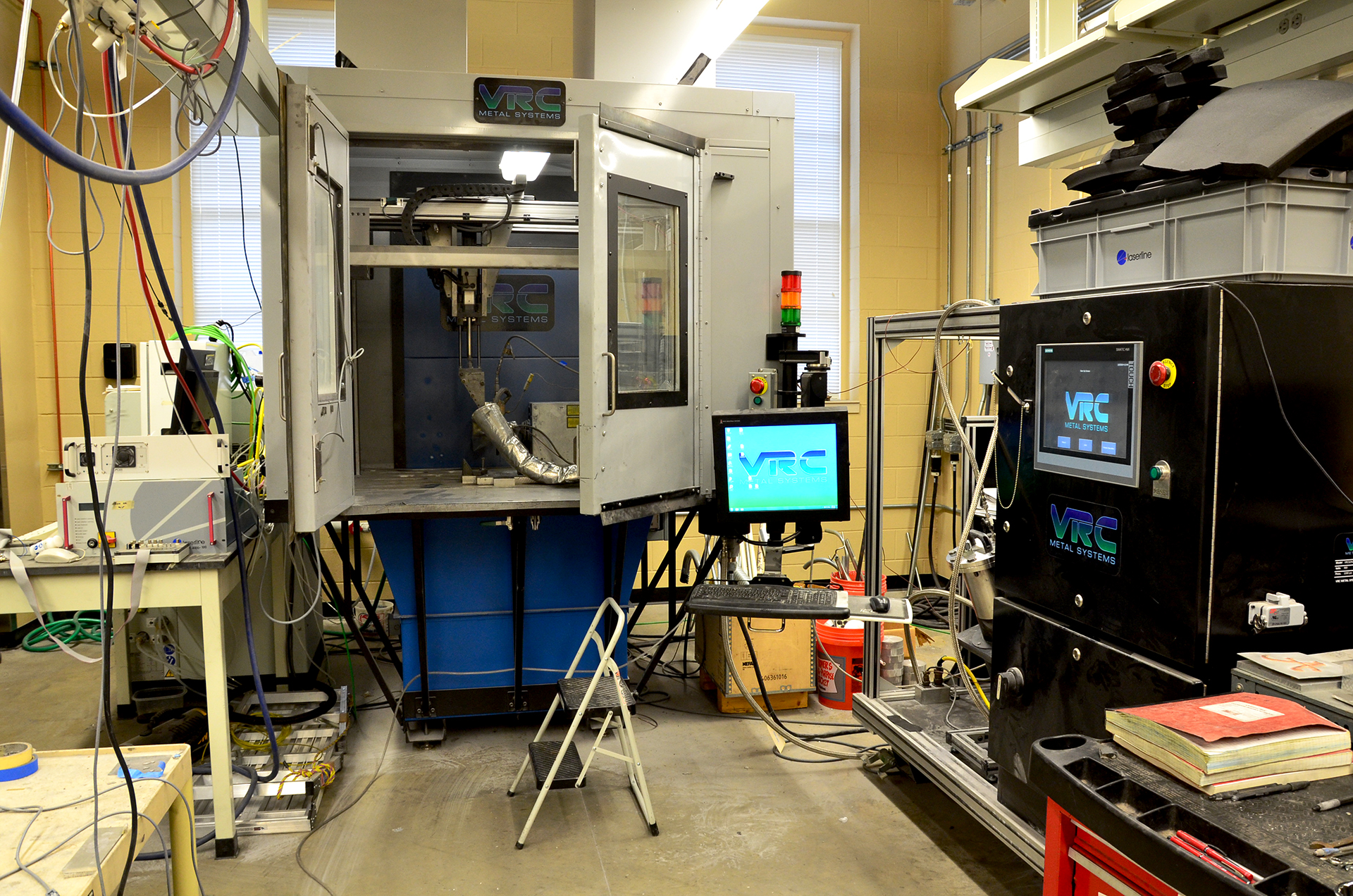

A transformative hybrid solid-state, high-shear additive manufacturing process, Additive Friction Stir-Deposition (AFS-D), is being researched to recycle metal waste/scrap at a forward operating base (FOB) to either fabricate new or repair existing components.

In this research, two specific metal waste streams from the deployed Military Occupational Specialty (MOS) units are identified (1) scrap metal from machine chips generated by maintenance-MOS activities and (2) expeditionary airfield (EAF) aluminum landing mats from EAF-MOS activities. These two waste streams generate chips and metal strips, respectively, that have been processed by AFS-D. Whereas in the novel solid-state AFS-D process, metals are deposited additively, layer-by-layer through a hollow rotating tool.

The proposed low-power approach incorporates the advantages of additive manufacturing and grain refining into a single process, allowing fabrication of small and large parts with superior build rates yielding enhanced mechanical properties. The process has been demonstrated with both powder and solid feedstock material. Very importantly for FOB use, the AFS-D process does not require metal powders, which can be difficult, energy intensive, or impractical to produce in-theater.

Affiliated Interdisciplinary Faculty

| Faculty | MPNC Title | Department |

|---|---|---|

| Director |

Metallurgical and Materials Engineering |

|

| Associate Director |

Metallurgical and Materials Engineering |

|

|

Civil, Construction and Environmental Engineering |

||

|

Civil, Construction and Environmental Engineering |

||

|

Computer Science |

||

|

Chemical and Biological Engineering |

||

|

Aerospace Engineering and Mechanics |

||

|

Geological Sciences |

||

|

Metallurgical and Materials Engineering |

||

|

Geological Sciences |

||

|

Electrical and Computer Engineering |

||

|

Information Systems, Statistics and Management Science |

||

|

Physics and Astronomy |

||

|

Electrical and Computer Engineering |

||

|

Physics and Astronomy |

||

|

Information Systems, Statistics and Management Science |

||

|

Mechanical Engineering |

||

|

Aerospace Engineering and Mechanics |

||

|

Chemistry |

||

|

Metallurgical and Materials Engineering |

||

|

Mechanical Engineering |

||

|

Civil, Construction and Environmental Engineering |

||

|

Metallurgical and Materials Engineering |

||

|

Information Systems, Statistics and Management Science |